Indian metal casting industry is booming at a rapid pace and looking at the present scenario one concept that has gained its popularity in past couple of years is "Casting Cost Estimation". These days the competition has grown at the phenomenon rate and in order to survive and compete at a global platform, metal casting industry has to meet ever increasing customers' expectations in terms of quality standards and lower pricing.

Casting process planning generally consists of proper choice of suitable casting process and various materials. Now in order to have continuous cost reduction in casting process, it is essential to build up an easy-to-use casting cost estimation methodology. It is also important to note that any comprehensive casting cost estimation methodology must have ability to identify the most important parameters in casting cost. The most important attributes of casting are cost estimation of material and tooling process.

Material Cost EstimationIn material cost estimation the two vital factors that plays the major role are cost estimation of in-direct and direct materials.

Direct Material Cost : Now in case of direct material cost, the cost estimation is made on materials like cast metal or alloy that appears in any product constitutes. However, in case of direct material cost, the metals or alloys that are used can be determined from casting weight. Direct material cost can be measured as:

C = c unit_metal x ; wcast × fm ×fp ×ff

Where, Cunit_metal = Unit metal cost

Wcast = Casting weight = pc × Vcast

pc= Casting metal density

Vcast = Casting volume

fm, fp, ff = Factors for metal loss in melting, pouring and fettling respectively

In-direct Material Cost : Depending upon the casting process in-direct materials consist of moulding sand, dispensable cores and feeding aids. Moreover the most essential point that one need to consider in case of in-direct material cost is the price of moulding sand. The price of moulding sand actually relies upon on the type and composition of sand, and size of mould. The cost of core ore sand also depends on the kind of sand and quantity of cores. In addition to this the cost modifiers are need to understood very effectively for mould rejection or core rejection. Indirect material cost can be calculated as:

x frm/n mould sand= Cms xWms frm /nc

Cost core sand = Cs Wcs fcc frc

Where,

nc= Number of casting (cavities) per mould

Cms= Cost per unit weight of mould sand (1NR/Kg)

Ccs = Cost per unit weight of core sand (1NR/Kg)

frm = Mould rejection factor

f cm = Mould sand recycling factor

f cc = Core sand recycling factor

f rc = Core rejection factor

Wms= Weight of mould sand

Wcs= Weight of core sand

Now the point to be noted is in case of indirect material cost sand recycling factor plays a very significant function. It helps in indicating the actual quantity of new sand required for each mould or core. The rejection factor is considered to measure the account breakages or damages. Moreover, the mould sand cost is finally divided by the number of casting cavities to find the price of mould sand cost per casting.

Tooling Cost EstimationTooling is the most important aspect in casting and thus its cost estimation can't be simply ignored. It consists of outline and core box for sand casting and metal mould for die casting in addition to investment casting. Their cost is determined by the material and manufacturing of the tooling and the material is selected depending upon the tool life required, which is further influenced by the order quantity.

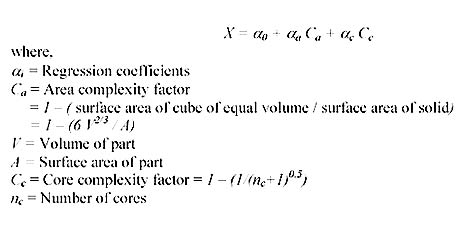

Certainly the tool manufacturing cost is determined by its geometric complexity and the complexity can be calculated as:

However, the important point to note in this case is the area complexity factor is normally calculated by evaluating the surface area of a part with respect to the surface area of a cube of equal volume. This is based on the assumption that a cube is the simplest shape and has the least surface area for a given volume.

Today estimating the cost of casting has become one of the major factors for the growth of any metal casting industry. The successful completion of any project largely depends on the proper and precise cost estimation of casting. As a project is proposed and then developed, an effective forecasting the cost of future projects is vital to the survival of any business or organization. From an owner's perspective the cost estimate actually help in determining the project scope. So if you are one of the players in this casting industry make sure to have casting cost estimation for successful project completion.