Squeeze casting is a combination of casting and forging process. The process can result in the highest mechanical properties attainable in a cast product. The development of squeeze casting process, can usher in tremendous possibility for manufacturing of components of aluminium alloys, which are not properly commercialized as yet. It can also be effective in for import substitution of critical components.

Squeeze casting is a combination of casting and forging process. The process can result in the highest mechanical properties attainable in a cast product. The development of squeeze casting process, can usher in tremendous possibility for manufacturing of components of aluminium alloys, which are not properly commercialized as yet. It can also be effective in for import substitution of critical components.

The process starts when the molten metal is poured into the bottom half of a pre-heated die. As soon as the metal starts solidifying, the upper half of the die closes and starts applying pressure during the solidification process. The extent of pressure applied is significantly less than that in forging. Parts of great detail can be produced. Coring can be used in tandem with the process to form holes and recesses. The high pressure and the close contact of molten alloy with the metal die surface results in minimum porosity and improvised mechanical properties. This process can be used for both ferrous and non-ferrous metals. This technique is very much suited for making fiber-reinforced castings from fiber cake preform.

Squeeze Casting Process (or squeeze forming) are of two types: Direct (liquid metal forging)This is done in equipment which closely resemble the forging process. Liquid metal is poured into lower die segment, contained in a hydraulic press. Upper die segment is closed. A very high pressure of 100 Mpa or more is applied to the whole cavity until the part gets solidified.

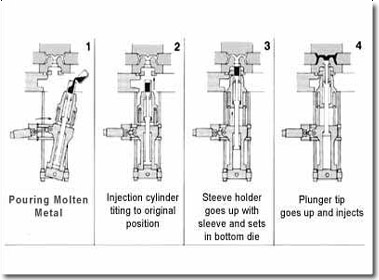

Indirect Squeeze CastingThis process is very much similar to die casting. It takes place in a die casting equipment. This equipment van be vertical or horizontal. The melt which is cleaned and grain -refined is poured in to the shot sleeve of a horizontal or vertical casting machine. The melt is then injected into the die through relatively large gates. This is accomplished through relatively slow velocity (less than 0.5m/sec).

The melt in the die cavity is then solidified under pressures, ranging from 55MPa to 300MPa. In this process the parts displays good tensile strength.

Squeeze casting is an economical, simple and convenient process. It has found extensive application in automotive industry in producing aluminium front steering knuckles, chassis frames, brackets or nodes. High capacity propellers for boat-engine.