Castings in copper base alloys, cast iron, aluminum

alloys and others like zinc can be produced using this method. Though most

of the end product is of aluminium castings. Typically the weight can range

from ½ kg to 50kg.

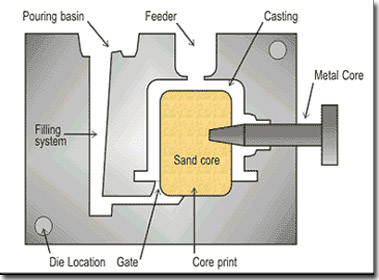

The production of castings starts with selecting either a reusable mold or a die having two or more parts. The die would be complete with the impression of the casting along with running, feeding and venting systems. There is provision also for removal of the casting. To maintain the casting's accuracy, the die can easily be cleared of debris such as hot metal splashes and sand. The die is quite capable of a regular cycle of production along with fast dissipation of heat of the metal poured into it.

Both simple and complex quality castings can be produced. A unique feature of the gravity die casting method is that it can handle heat treatment of high strength aluminum alloys that pressure die casting still cannot. Suitable for castings requiring complex intricate coring and small production runs