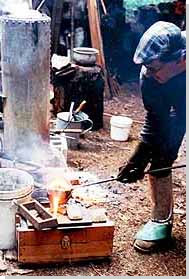

A home foundry has different objectives and requirements from a commercial foundry. For instance, a home foundry generally does not have to pass government inspections and regulations, such as OSHA. However, this is no excuse, to not follow some simple safety measures and guidelines.

A home foundry has different objectives and requirements from a commercial foundry. For instance, a home foundry generally does not have to pass government inspections and regulations, such as OSHA. However, this is no excuse, to not follow some simple safety measures and guidelines.

Metal casting is inherently a dangerous activity that have possible injurious or fatal consequences. Hence these activities should be performed with good judgment and caution on the part of practitioner. Although majority of hobby metal workers have not suffered have serious injury, the potential still exists for a broken crucible, steam explosion, or other mishap to occur, and one should be prepared in order to survive such crises.

Investment in the proper protective clothing is essential, including leather welding chaps and jackets, leather boots with steel toes, insulated leather gloves, and full face and eye protection. Make sure that you have a clear working area during pours and avoid walking backwards with a load of hot metal. Never pour across a concrete floor, or damp ground.

While most of the casting alloys are reasonably safe when properly used, one must work in a properly ventilated area to avoid breathing any poisonous fumes from the melt or from fluxes, or from the burner itself. Melting scrap alloys of uncertain composition may expose one to fumes of lead, arsenic, cadmium, and other harmful. Don't forget to keep a dry chemical fire extinguisher and a bucket of dry sand handy in the case any spills ignite something. Carefully check all propane fittings for leaks before use, and never operate a furnace unattended.

There is a particular safety concern in the foundry industry about moisture and moisture that can be hazardous even in small amounts. When molten metal comes in contact with moisture or water, due to the heat-induced expansion of water from liquid to steam, an explosion may occur. Accordingly, the standard covers safe zones, run-out pits and other protection strategies can be employed.

Be safe though, whatever safety equipment you use / wear will never be sufficient! Do not even approach any type of furnace without welding gauntlets as a minimum, and do not wear any synthetic clothing.

Safety Equipment & ClothingSome of the common safety equipment that have found to be useful in home foundries are -

- Wear leather work boots, preferably with steel toes.

- Wear trousers, not shorts and long sleeve shirt or welder's vest.

- Wear loose-fitting leather clothes, or at least clothes made of a material, which is fairly flame resistant.

- Welder's gloves or other leather gloves with long gauntlets up the arm have proved to be of immense help.

- Safety glasses are an absolute minimum. It is wise to wear a full-face shield as well.

- Long-handled pliers (or tongs) and three foot 1/4" rod. The pliers are designed for adding things to the crucible and adjusting coals, etc. The rod is used for mixing the contents of crucible and move dross to the side just before pouring.