|

|

Use of titanium and titanium alloys started in the early 1950s. Soon, it becomes very popular with the aerospace, energy, and chemical industries around the globe. Titanium and its alloys are the best material choice for various critical applications because of their high strength-to-weight ratio, excellent mechanical properties, and corrosion resistance features. Titanium alloys are used for many critical hi-tech applications, such as rotating and static gas turbine engine components and parts of aircraft engines.

Other application areas of titanium alloys are :| Nuclear power plants | Food processing plants | Oil refinery heat exchangers |

| Marine components | Medical protheses |

Almost 80% of all the titanium produced worldwide is used in the aerospace industries.

|

Titanium is a light, strong, lustrous, corrosion-resistant transition nonferrous metal. It can be easily alloyed with other elements/metals including iron, aluminum, vanadium, molybdenum and others, for producing strong lightweight alloys for aerospace and other demanding applications. Titanium's advantages can be summarized as follows:

- Elevated temperature 350°F-1000°F service capability

- Excellent fatigue and fracture resistance

- Excellent strength-to-weight ratio

- Compatibility with carbon/epoxy materials

- It is used as part of the containers of batteries and as anode in alkaline batteries.

- Biocompatibility

- Superior oxidation and corrosion resistance

- Non-magnetic character

- Fire resistance

- Short radioactive half life

Types of Titanium Alloys

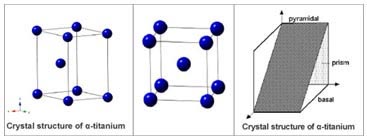

Titanium alloys are classified as Alpha (a), Alpha-Beta (a-ß), and Beta (ß) alloys on the basis of alloying elements they contain. The following table explains and compares these three titanium alloys:

| Alpha Alloys (a) | Alpha-Beta Alloys (a-ß) | Beta Alloys (ß) |

| Alpha alloys commonly have creep resistance superior to beta alloys. Alpha alloys are suitable for somewhat elevated temperature applications. They are also sometimes used for cryogenic applications. Alpha alloys have adequate strength, toughness, and weldability for various applications, but are not as readily forged as many beta alloys. Alpha alloys cannot be strengthened by heat treatment. | Alpha-Beta alloys have chemical compositions that result in a mixture of alpha and beta phases. The beta phase is normally in the range of 10 to 50% at room temperature. Alloys with beta contents less than 20% are weldable.The most commonly used titanium alloy is Ti-6Al-4V, an alpha + beta alloy. While Ti-6Al-4V is fairly difficult to form other alpha + beta alloys normally have better formability. | Beta alloys have good forging capability. Beta alloy sheet is cold formable when in the solution treated condition. Beta alloys are prone to a ductile to brittle transition temperature. Beta alloys can be strengthened by heat treatment. Typically beta alloys are solutioned followed by aging to form finely dispersed particles in a beta phase matrix. |

Followings are the few common titanium alloys according to the above classifications:

| Alpha Alloys (a) | Alpha-Beta Alloys (a-ß) | Beta Alloys (ß) |

| Ti-2.5Cu | Ti-6Al-4V | Ti-13V-11Cr-3Al |

| Ti-5Al-2.5Sn | Ti-6Al-6V-2Sn | Ti-8Mo-8V-2Fe-3Al |

| Ti-8Al-1V-1Mo | Ti-6Al-2Sn-2Zr-2Cr-2Mo | Ti-10V-2Fe-3Al |

| Ti-6242 | Ti-3Al-2.5V | Ti-15-3 |

| Ti-6Al-2Nb-1Ta-0.8 Mo | Ti-8Al-1Mo-1V | ----- |

| Ti-5Al-5Sn-2Zr-2Mo | ----- | ----- |

More Applications of Titanium Alloys

- Artillery (howitzers)

- Turbines (power generation)

- Manned and unmanned aircraft (commercial and military aircraft, rotorcraft)

- Automotive (motorcycles, performance automobiles)

- Military vehicles (tanks, hovercraft) .

- Naval and marine applications (surface vessels, subs)

- Sports equipment (bicycle frames, golf clubs)

- Chemical processing plants (petrochemical, oil platforms)

- Consumer electronics (batteries, watches)

- Pulp and paper industry (washing and bleaching systems)

- Medical devices (implants, instruments)

- Architecture (sculptures)