The technique that is used in manufacturing of thermoplastic and thermosetting plastic materials is called as injection molding. There are various materials that take its part in the process. Some to name are thermoplastic materials like polystyrene, acrylonitrile butadiene styrene also called as ABS in short, nylon, polypropylene, polyethylene, and polyvinyl chloride.

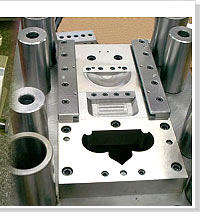

The machines used for injection molding is called as presses. These machines contain the mold in which shape of the components must be made. Molds are normally expensive and used only in mass production units. The design of the mold is normally in two parts core and the cavity.

It is possible to use the mold and produce several images of the same part in single production shot. There are two methods used for building molds. They are standard machining and EDM machining. The injection molds is generally build using standard machining method, which is later, replaced by advanced CNC machines where accuracy and precision attained is much more.

The EDM also called, as electrical discharge machining or spark erosion is the most commonly used process for mold making. Thus the cost of manufacturing mold depends on lot of factors. The factors are number of cavities, size, mold used, complexity involved in manufacturing process, finish needed, longevity and so on.

Cycle in Injection Molding Process:The process of injection molding involves the following cycle steps. They are:

- Mold close

- Injection carriage forward

- Inject plastic

- Metering

- Carriage retract

- Mold open

- Eject parts

Proper car must be taken while carrying out the cycle for injection molding process. To name some in this direction are cooling must be done properly which others would result in distorted molding.

Care must be taken while filling new mold. One of the steps that could be taken while tying out new mold filing is to carry out the process of molding trial. That is trying the molding trial for smaller size with small pressure and temperature applied. Once this product comes out successfully then a setting sheet can be prepared and process can be carried out for larger quantities by workforce.

It is also essential to take steps for review and studying the process of injection molding. The review must be done by checking injection speeds, which is got by performing viscosity curves. The melt temperatures and pressures are varied at regular intervals and reviews must be done. Pressure drops area checked to find out whether pressure is maintained correctly in machines. After the whole cycle of injection molding process is finished the mold is opened and product is ejected using ejector pins. Thus the process of injection molding is a complex process, which if not carried out can produce various defects.

The defects may arise due to defects in the molds or defects in the process of molding. The various defects that could creep up during the process of injection molding if not carried out properly are the blister, burn marks, color streaks, delamination, flash, flow marks, embedded contaminates, jetting, silver streaks, sink marks, short shot, splay marks, voids, stringiness, weld line and warping.

Thus proper cares and essential review steps must be done while carrying out injection molding process to avoid such defects.