Tungsten is one of those metals, which rely heavily on the recycling of tungsten scrap (W Scrap) and tungsten alloy scraps (W Alloy Scrap). When we talk about a high temperature scrap metal or a high temperature alloy scrap, tungsten and tungsten alloy scraps top the list. With a melting temperature of 3422 0C, tungsten and tungsten alloy scraps are only second to carbon.

Tungsten is one of those metals, which rely heavily on the recycling of tungsten scrap (W Scrap) and tungsten alloy scraps (W Alloy Scrap). When we talk about a high temperature scrap metal or a high temperature alloy scrap, tungsten and tungsten alloy scraps top the list. With a melting temperature of 3422 0C, tungsten and tungsten alloy scraps are only second to carbon.

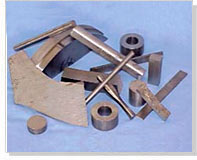

Such a high temperature scrap metal and high temperature alloy scrap, tungsten scrap and tungsten alloy scrap can be recycled for uses and applications in high temperature conditions, like - filaments in light bulbs as well as several other electronics. However these scraps can also be used in the cases, where they are alloyed with other scrap metals to produce super alloys. The tungsten scrap and tungsten alloy scrap super alloys can be used to make transportation / machinery equipment and heat and radiation shielding.

Today, there is a global trade in the buying and selling of high temperature scrap alloys that involve several companies across the globe. According to forecasts, the volume for both buyers and sellers will continue to increase in the future.

| Pure Tungsten | Tungsten Carbide Inserts |

| Mallory | Tungsten Carbide Drills |

| Densalloy | Elkonite |

| Hevimet | Tungsten Carbide Morgan Rolls |

| Tungsten Carbide End Mills | Tungsten Carbide Dies |

| Tungsten Carbide Micro Drills | Tungsten Carbide Circuit Board Drills |

Types / Grades of Tungsten Scrap

Different grades and varieties of tungsten scrap are used for recycling purposes and to recover pure tungsten from the scrap. Given in the table below are some of the important grades / types of tungsten used in recycling-

| Grade | Details |

| Mixed Tungsten Carbide Cutting Inserts | It comprises of assorted clean tungsten carbide cutting inserts. These inserts come in different sizes, including - square, rectangle, triangle, hexagon or octagon. |

| Coated Tungsten Carbide Cutting Inserts | This grade of tungsten metal consists of coated tungsten carbide cutting inserts. These inserts come in various shapes such as square, rectangle, triangle, hexagon or octagon. |

| Clean Tungsten Carbide Cutting Inserts | In includes clean sorted un-coated tungsten carbide cutting inserts. These come in varied sizes, such as square, rectangle, triangle, hexagon or octagon. |

| Filiment Scrap | This grade of tungsten metal comprises of clean sorted tungsten filaments. It may also include tungsten filaments from incandescent light bulbs. |

| T~1 Tool Steel Scrap | It includes common T=1 tool =steel and has a chemical composition of 0.70% carbon, 4.0% chromium, 12.0% tungsten, 5.0% vanadium, balance iron. |

| T~5 Tool Steel Scrap | It includes common T=5 tool steel and have a typical composition of 0.80% carbon, 8.0% cobalt, $.0 % chromium, 18.0% tungsten, 2.0% vanadium and the balance iron. Some common items made of this grade of tungsten scrap, include - lathe & planer tools, cutoff tools, form tools. |

| T~15 Tool Steel Scrap | This grade of tungsten scrap consists of T=15 tool steel and have a chemical composition of 1.5% carbon, 5.0% cobalt, 4.0% chromium, 12.0% tungsten, 5.0% vanadium and the balance iron. Some of the common items made of this grade of tungsten scrap include - broaches, punches, milling cutters, lathe & planer tools. |

| Tungsten Sludge | It consists of a variety of tungsten content sludges. |

| Other Tungsten Scrap | It include other tungsten and tungsten alloy materials, which are not included in the list. |

Titanium Scrap & Titanium Alloy Scrap

The recycling of tungsten scrap is by no means a modern technique. On the contrary, it has been established for several decades. Even before anyone thought about the recycling of paper, glass, and aluminum - as is common today in most of the industrialized nations - a considerable quantity of tungsten was reclaimed from various types of scrap. This is due to the fact that, most of the tungsten ores contain less than 1 wt% WO3 and very rarely high concentrations.

Tungsten Recycling MethodsA variety of tungsten recycling methods are available, which can be broadly categorized into four types -

- Hydro Metallurgy

- Melting Metallurgy

- Direct Recycling

- Semi-direct Recycling

Hydro Metallurgy

In hydro metallurgical recycling, chemical methods are used to recover tungsten from scrap. The recovered tungsten is used as a substitute for tungsten ore concentrates at conversion plants. This processing method, results in tungsten materials, which were indistinguishable from those developed from ore concentrates.

Melting MetallurgyMelting metallurgy is a tungsten recycling method, wherein scrap is used as a source of tungsten in the production of alloys, such as stellites, steels, super alloys; cast or menstruum tungsten carbide; or ferro tungsten or tungsten melting base.

Direct RecyclingIn this method of recycling, the scrap is disaggregated into a powder by chemical and / or physical means without changing its actual composition.

Semi-direct RecyclingIn semi-direct recycling, one component of the scrap is dissolved chemically that allows the scrap to be broken down by physical methods.